What is an aluminum brazing alloy?

An aluminum brazing alloy is a filler metal made from aluminum as a matrix with other metallic elements (such as silicon, copper, zinc, and magnesium). Its core function during the brazing process is to form a strong metallurgical bond on the surface or in the gaps between the aluminum materials being joined by melting itself (having a melting point lower than that of the aluminum base metal being joined), ultimately achieving a connection.

Two key differences are important to clarify:

Unlike fusion welding, aluminum brazing does not melt the base metal. Instead, the filler metal (i.e., the aluminum brazing alloy) melts to fill the gap, thus avoiding the damage to the base metal caused by high-temperature melting.

Unlike pure aluminum, pure aluminum has a high melting point (approximately 660°C), resulting in low joint strength and poor corrosion resistance. However, brazing alloys aluminum, through the addition of alloying elements, lower the melting point (typically between 450-620°C, suitable for aluminum processing) while also improving key joint properties such as strength and corrosion resistance.

Applications of Aluminum Brazing Alloys

The application of aluminum brazing alloys has clear application thresholds, primarily targeting aluminum joining applications requiring high precision, low deformation, and high sealing performance.

When joining thin parts (e.g., aluminum tubes less than 1mm thick) or complex structures (e.g., multi-pass heat exchangers), fusion welding can easily cause deformation or burn-through, making aluminum brazing alloys a preferred choice.

When products require high sealing performance (e.g., air conditioning refrigerant pipes and water tanks), aluminum brazing effectively prevents leaks and creates smooth joints that do not affect fluid flow.

When mass production is required (e.g., automotive radiators and household appliance evaporators), aluminum brazing can be integrated with automated production lines for efficient processing and cost reduction.

Common Classifications

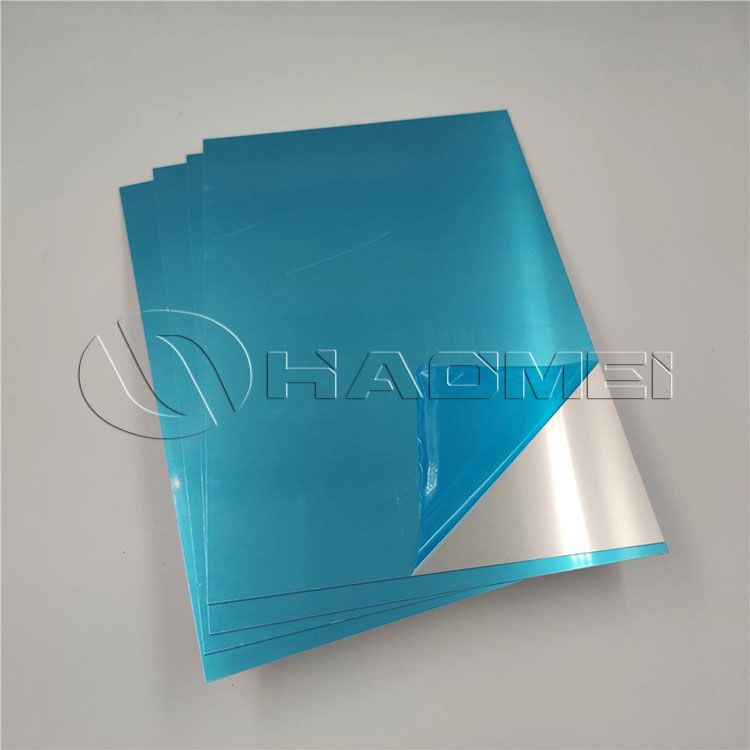

Al-Si alloys: The most commonly used type, with a silicon content typically between 6% and 13%. Silicon significantly lowers the melting point of aluminum, resulting in joints with high strength and excellent corrosion resistance. This aluminum brazing sheet is suitable for joining most pure aluminum and aluminum alloys (e.g., 3003 and 5052), such as household appliance condensers and automotive intercoolers.

Al-Si-Cu alloys: Copper (1%-5%) is added to Al-Si to further enhance the high-temperature strength of the joint, making them suitable for applications with higher operating temperatures, such as pipe connections around automotive engines. However, please note that the addition of copper may slightly reduce corrosion resistance, so environmental evaluation is required before use.

Al-Si-Zn alloys: Zinc (5%-10%) is added. Their primary advantage is a lower melting point (down to approximately 450°C), making them suitable for joining thin-walled aluminum materials or dissimilar metals (such as aluminum and copper) that are sensitive to heating temperatures. However, their strength is relatively low, making them primarily used in low-load applications.

Core Performance Requirements

When selecting an aluminum brazing alloy, consider more than just the composition. The following four key properties directly determine the joint's effectiveness:

Melting Point Compatibility: The melting point must be lower than the base material's melting point (typically at least 30-50°C lower) to prevent deformation, but not too low, as this will affect the joint's high-temperature performance.

Flowability: After melting, the alloy spreads evenly across the base material's surface and smoothly fills gaps (especially narrow ones). Poor flowability can lead to defects such as voids and incomplete penetration in the joint.

Joint Strength: The tensile and shear strengths of the joint formed after cooling must meet application requirements. For example, the tensile strength of automotive aluminum brazing alloy joints is typically required to be ≥100 MPa.

Corrosion Resistance: The joint should be resistant to corrosion in humid, acidic, or alkaline environments. This is especially true for components used outdoors or exposed to liquids (such as water tanks and seawater equipment). Select Al-Si alloys or magnesium-added alloys with excellent corrosion resistance.