5000 Series Aluminum for Notebook Back Panel

Publish Time: 2025-07-04 Origin:https://www.hmaluminumsupply.com

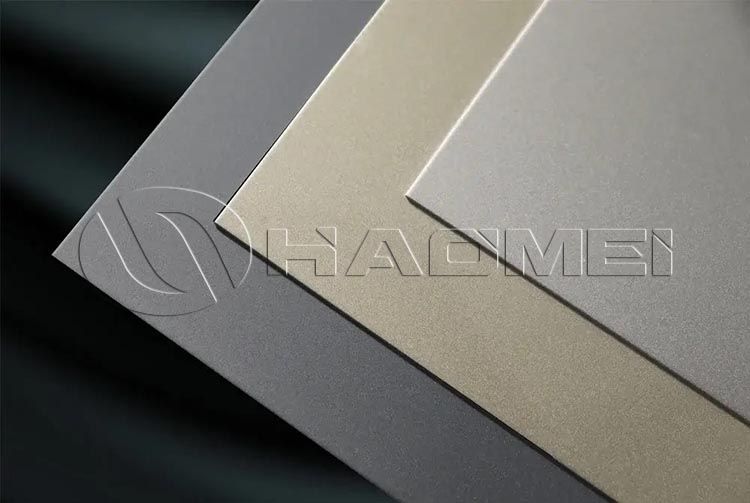

The main alloying element of 5 series aluminum sheet is magnesium (Mg), which belongs to the aluminum-magnesium alloy series. This series of aluminum sheets has medium strength, and its tensile strength will continue to increase with the increase of Mg content, and the surface hardness will also increase accordingly.

In addition to its strength advantage, the 5 series aluminum plate also has good corrosion resistance, which can effectively resist corrosion factors in the daily use environment, ensuring that the notebook back panel is not easy to rust or damage during long-term use. In addition, its processing performance and welding performance are also relatively excellent, which provides the possibility for complex processing technology of notebook back panels.

5052 aluminum sheet

The Mg content of anodizing 5052 aluminum is moderate and it is widely used in the manufacture of notebook back panels. Among them, the 5052-O aluminum plate is in the annealed state, with uniform internal structure, low hardness and good plasticity. This allows it to easily cope with complex processes such as deep stamping and stretching that require large deformations in the early stages of back panel processing. For example, some notebook back panels with special curved shapes often use 5052-O aluminum plates to ensure accurate shaping.

The 5052 h32 aluminum plate has been processed and hardened, and its strength and hardness have been significantly improved, and its fatigue resistance has been enhanced. After the back panel is basically formed, the use of 5052-H32 aluminum plate can effectively improve the overall strength and wear resistance of the back panel, making it better able to resist friction and collision in daily use, reduce surface scratches and deformation, and improve the durability of the notebook.

5083 alloy aluminum plate

5083 alloy is a high-magnesium alloy that cannot be strengthened by heat treatment, but it has excellent strength and corrosion resistance, can be cut and welded, and has good anodizing effect. In high-end notebook products, 5083-O aluminum plate provides convenience for the initial processing of complex shapes of the back panel with its good plasticity. When it is necessary to further improve the strength and stability of the back panel, 5083h111 is a better choice.

It retains a certain degree of formability and has improved strength. It can provide reliable protection for the internal components of the notebook. It is not easy to be damaged even by external impact. Its excellent anodizing characteristics can also give the back panel a variety of appearance effects, satisfying consumers' pursuit of texture.

5182 alloy aluminum plate

5182 alloy is often processed into thin plates for use, with good strength and certain formability. In the refined manufacturing of notebook back panels, 5182-O thin sheets can use good plasticity and precision processing technology to create a back panel with a complete structure that meets special appearance design requirements, achieving a more delicate surface texture or unique shape.

The 5182-H14 aluminum sheet has a certain strength and moderate hardness, which is suitable for subsequent surface treatment and assembly of the back panel, ensuring that the back panel has reliable structural strength while meeting aesthetic requirements.